Iron Ore Sinter

The ore is combined with other materials, fired, and heated to create the sinter in a sinter plant, which usually comprises of a number of sizable machinery. It is among the initial stages of the steel manufacturing process.

Sinter is essential to contemporary steelmaking because it guarantees the efficient utilization of iron ore fines in blast furnaces, which raises the process's total productivity and efficiency.

PRODUCT DESCRIPTION

Important Aspects of Iron Ore Sinter Purpose:

The main goal of sintering is to produce sinter, or bigger particles of iron ore that may be charged into a blast furnace, hence increasing the efficiency of the iron extraction process. Sinter produces a more homogeneous material for reduction and increases the permeability of the charge in the furnace.

SINTERING PROCESS:

Raw Materials: Fuel (such as coke breeze), fluxes (such as dolomite or limestone), and fine iron ore are combined.

Agglomeration: This mixture is burned on a sizable moving grate in a sinter machine. The ore particles fuse together into larger chunks as a result of the heat.

Cooling: To prepare it for use in the blast furnace, the sintered ore is cooled and then broken up into smaller pieces.

ADVANTAGES:

Improved Productivity: Sintering helps increase the productivity of blast furnaces, making the process more efficient.

Use of Fine Ore: Iron ore fines that would otherwise be wasted can be used effectively in the sintering process.

Cost-Effective: By using iron ore fines and other locally available materials, sintering can reduce the cost of production.

Environmental Impact: Sintering can generate dust and emissions, but modern sintering plants often have measures like gas cleaning and dust suppression systems to minimize environmental impact.

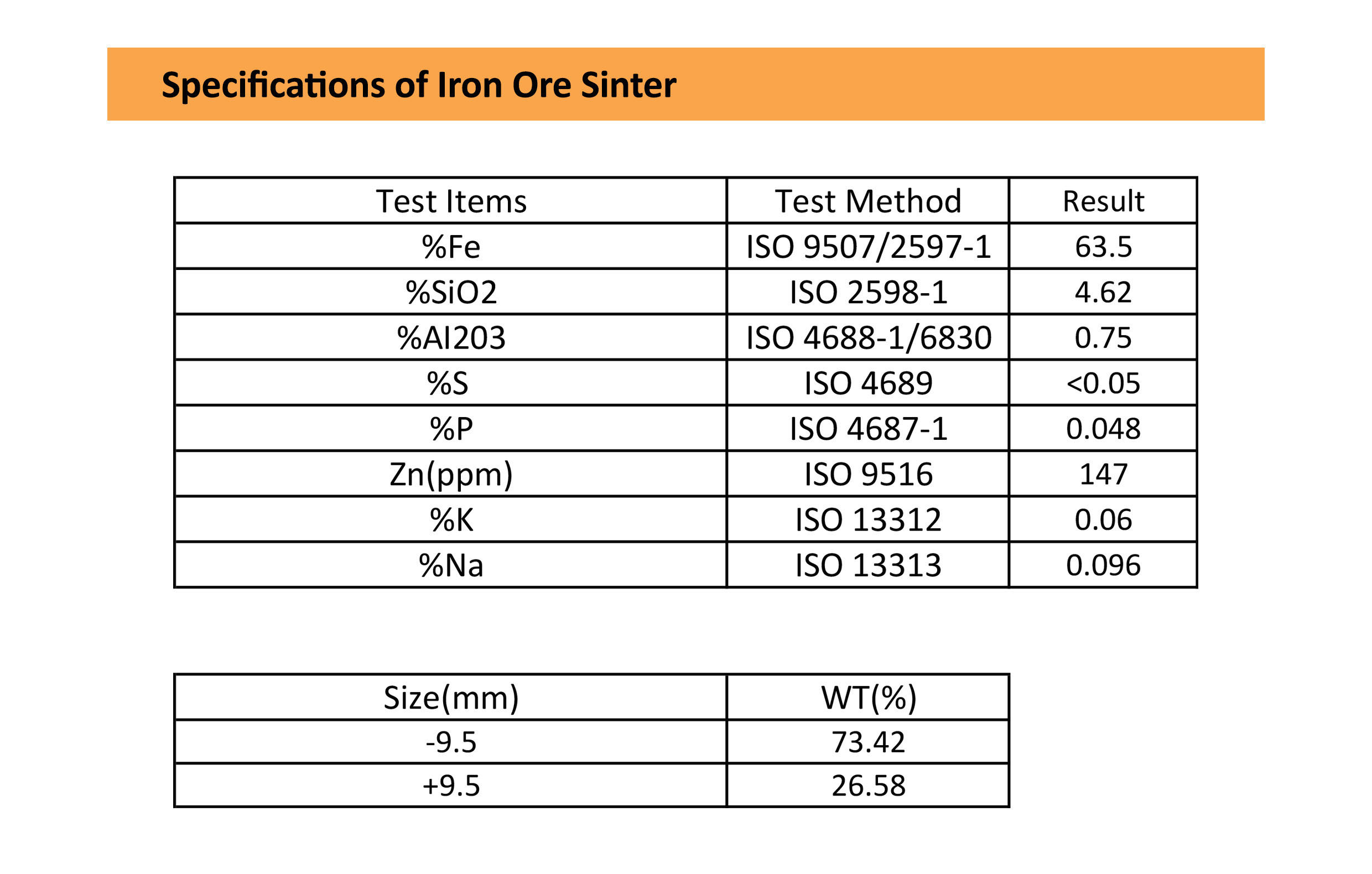

Sinter quality is influenced by a number of variables, including the chemical makeup of the ore, the sintering procedure, and the combination of fluxing agents. High-quality sinter is perfect for the blast furnace because it has a constant size, high porosity, and good mechanical strength.

In conclusion, iron ore sinter, which is made by sintering fine iron ore to create larger, more robust particles, is an essential component in the steelmaking process. It is essential for increasing the blast furnace process's efficiency.