Sponge Iron

Sponge iron, also known as Direct Reduced Iron, or DRI, is a type of iron that is created by reducing iron ore—usually in the form of magnetite or hematite—in a solid-state process with a reducing gas, usually carbon monoxide or hydrogen. A spongy mass of iron particles—known as "sponge iron" because of its porous structure—is the end result.

PRODUCT DESCRIPTION

Direct Reduced Iron (DRI), commonly referred to as sponge iron, is a premium iron product made by directly reducing iron ore (usually hematite or magnetite) with a reducing agent like coal or natural gas. The end product is a porous substance that is lightweight, manageable, and perfect for a range of steelmaking applications.

In electric arc furnaces (EAF) and induction furnaces, sponge iron is frequently utilized in place of scrap metal. It helps raise the grade of steel produced and offers steel producers affordable options because of its purity and high iron content.

KEY FEATURES

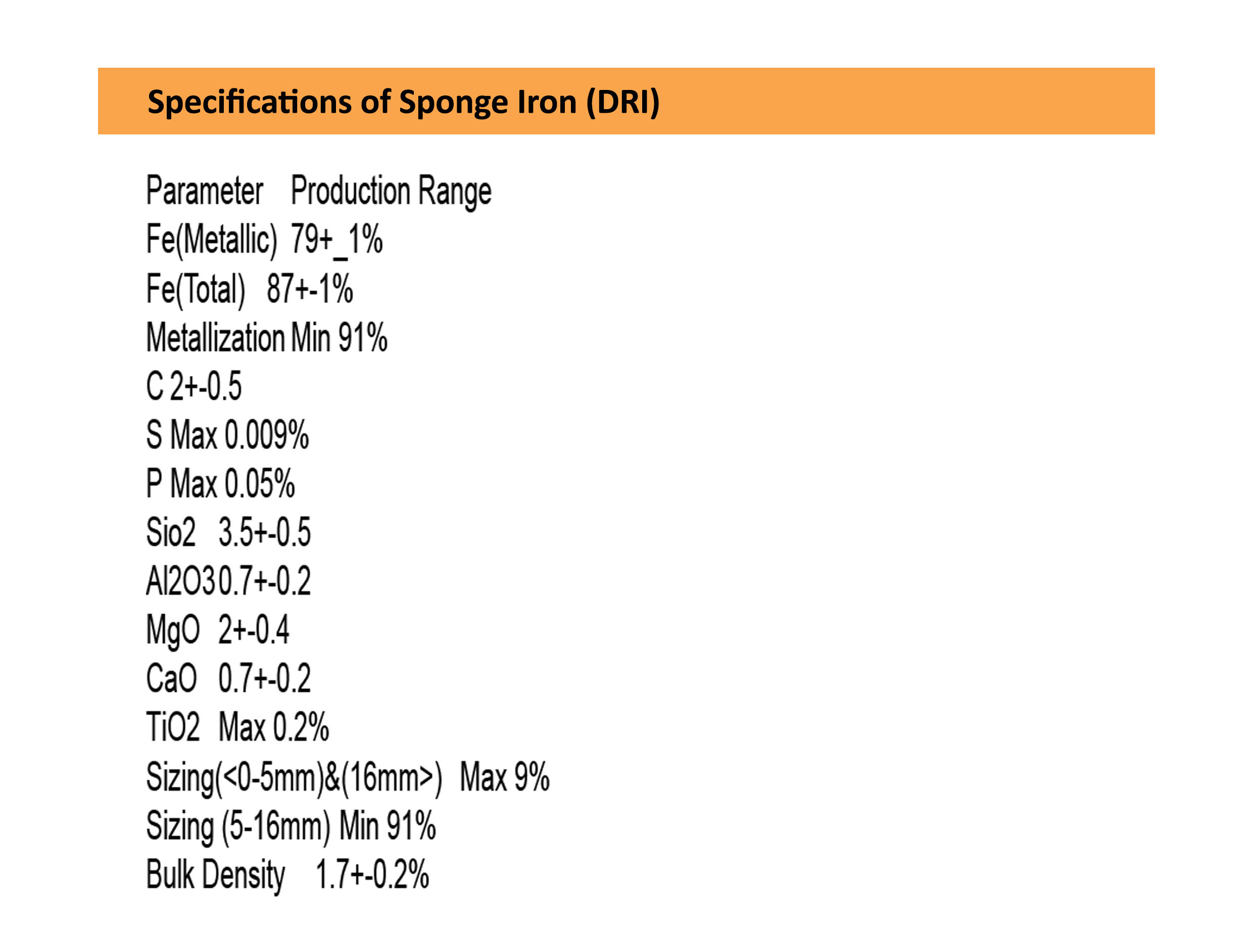

High Iron Content: With an iron content ranging from 90% to 94%, this material is ideal for making steel.

Low Impurities: The manufacturing of high-quality steel is aided by sponge iron's well-known low levels of phosphorus, sulfur, and other impurities.

Environmental Impact: By lowering carbon emissions throughout the steel production process, sponge iron provides a more environmentally friendly option than scrap metal.

Customizable Sizes: A variety of sizes are offered to satisfy certain client needs.

Steel Manufacturing: Induction furnaces (IF) and electric arc furnaces (EAF) use it as a charge material.

Foundries: Provides top-notch iron to foundries, especially for casting production.

Engineering and Automotive Industries: Sponge iron is utilized in the manufacturing of a number of components, including structural beams and automotive parts.

Iron & Steel Alloying: It is also utilized in the production of several iron and steel alloys.

BENEFITS

Cost-effective: It offers a less expensive option for the manufacturing of steel when compared to other iron sources.

High Efficiency: The sponge iron maintains a high iron content with little slag formation thanks to the direct reduction process.

Eco-friendly: Lowers carbon footprints by reducing reliance on conventional blast furnace ironmaking.

PACKING AND STORAGE

Packaging: 50 kilogram bags and bulk are also available (custom packaging options available).

Storage: Keep out of the wet and in a cool, dry location. When stored properly, it can be kept for a long time.