Concentrate Iron Ore

Iron ore that has been processed to raise its iron content and lower impurities like silica, alumina, and other gangue minerals is known as concentrated iron ore. Iron ore concentration is the term for this process, which usually include crushing, grinding, and isolating the valuable iron particles from trash.

To put it briefly, iron ore concentrate is the end result of beneficiation procedures that upgrade raw iron ore by eliminating impurities, producing a more iron-rich substance that is perfect for use in industrial processes like the manufacturing of steel.

PROCESS OF CONCENTRATION IRON ORE

The first step involves crushing and grinding the raw iron ore, which is typically found as big lumps or rocks. To make iron extraction easier, these smaller particles are further pulverized into a fine powder.

Magnetic Separation: Magnetic separation is one of the most widely used techniques for iron ore concentration. This method makes use of iron's magnetic qualities. The magnetic particles (iron minerals) are drawn to the ground ore and separated from the non-magnetic waste material by passing it through magnetic separators.

Flotation: Adding chemicals to a slurry of finely milled ore is a technique that is occasionally employed. As the waste material stays submerged, the iron minerals can float and be skimmed off because these compounds make them hydrophobic, or water-repellent.

Pelletizing: Concentrated iron ore may occasionally undergo additional processing to create pellets, which are tiny, spherical particles that are more manageable and effective for use in blast furnaces. In this process, the iron ore concentrate is heated in a furnace and agglomerated using a binder.

Unlock the Power of Nature – Premium Concentrated Iron Ore for Stronger Foundations!

ADVANTAGES OF CONCENTRATING IRON ORE

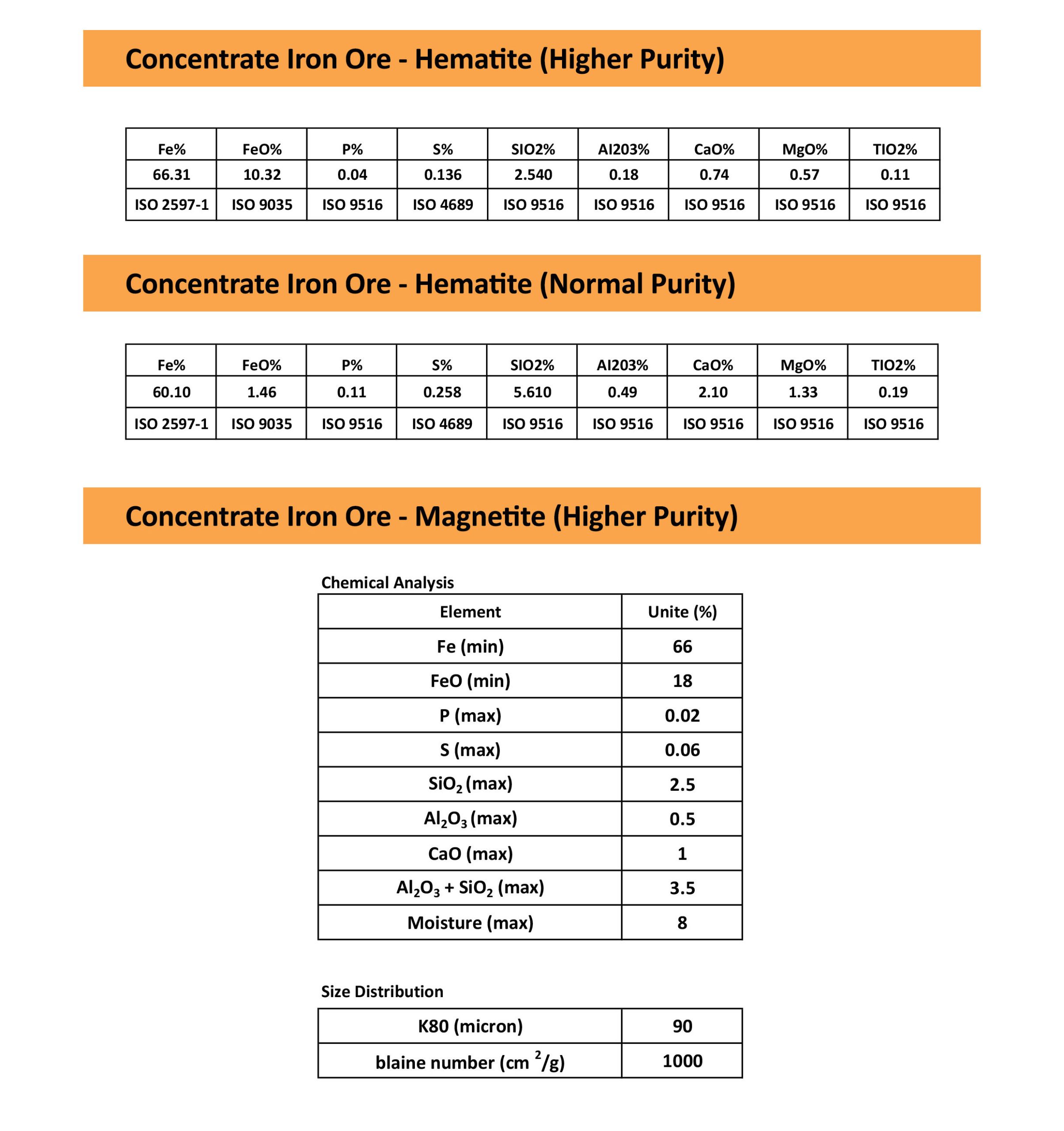

Increased Iron Content: By eliminating undesirable impurities from the ore, the concentration process raises the iron content percentage. Depending on the quality of the ore and the particular concentration techniques employed, the iron ore concentrate usually contains 60–70% iron.

Better Blast Furnace Performance: Because less energy is needed to extract iron, concentrated ore's higher iron concentration and purity contribute to blast furnaces' increased efficiency during the steel-making process.

Economic Efficiency: Valuable iron can be extracted from ores that would otherwise be too low-grade or unprofitable to mine thanks to the process of iron ore concentration.

FINAL APPLICATIONS FOR IRON ORE CONCENTRATE

The primary applications for iron ore concentration are:

The main basic ingredient for making steel, pig iron, is produced in blast furnaces.

Direct Reduced Iron (DRI): To create iron more efficiently, several steelmaking processes use concentrate for direct reduction.

Steelmaking: Whether in the form of pellets or sintered form, concentrated iron ore is crucial to the steelmaking process.