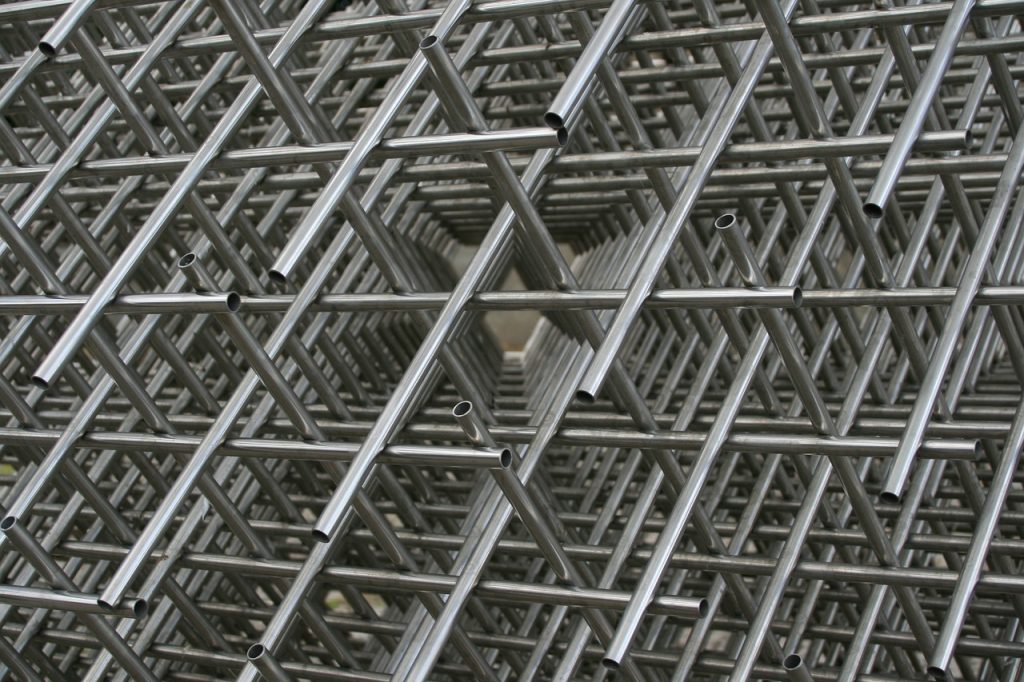

Steel Pipes and Tubes

Various grades of steel, including carbon, stainless, and galvanized steel, are used to make steel pipes and tubes, based on the particular needs, such as corrosion resistance, strength, and durability. Both are extensively utilized in a variety of industries, including manufacturing, transportation, energy, and construction.

TYPES OF STEEL PIPES AND TUBES

1. Seamless Steel Pipes and Tubes

2. Welded Steel Pipes and Tubes

- Cost-effective solutions for general applications, made by welding steel sheet edges together.

- Fit for usage in HVAC, plumbing, and water systems, as well as lower-pressure applications.

3. Galvanized Steel Pipes and Tubes

- Applied a zinc coating to improve longevity and prevent corrosion.

- Frequently utilized in marine environments, agricultural sectors, and outdoor applications.

4. Stainless Steel Pipes and Tubes

- Constructed from premium stainless steel, which provides outstanding resistance to wear, heat, and corrosion.

- Perfect for usage in sectors where corrosion resistance and hygienic practices are essential, like food processing, pharmaceuticals, medical equipment, and more.

5. Carbon Steel Pipes and Tubes

- Carbon steel pipes and tubes are well-known for their resilience to harsh environments and are frequently used in applications where strength is crucial.

- Widely utilized in heavy-duty machinery, infrastructure, and construction.

STEEL PIPES

Steel pipes are commonly used for the delivery of liquids and other

commodities. They are available in a variety of sizes along with quality

levels, depending on the environment and purpose. Since steel pipes' main

function is to facilitate the flow of gases or liquids, attention is typically

drawn to their inner size.

1. Pipelines for Gas and Oil

2. Systems for Supplying Water

3. Systems for Heating and Cooling

1. Seamless Steel Pipes are produced by burning a solid steel alloy to form a seamless pipe.

2. Steel Sheets or Strips are joined together to develop welded steel pipes.

STEEL TUBES

Similar to pipes, steel tubes tend to be used for more

powerful mechanical and structural purposes. The primary distinction is that

steel tubes are flexible for specific construction and engineering applications

since they are characterized by both their outer diameter and wall thickness.

Applications requiring strength, resistance to pressure, or precise mechanical

properties frequently use tubes.